Heat transfer of I-section steel beam subjected to localised fire

Developed by Zhuojun Nan

Introduction

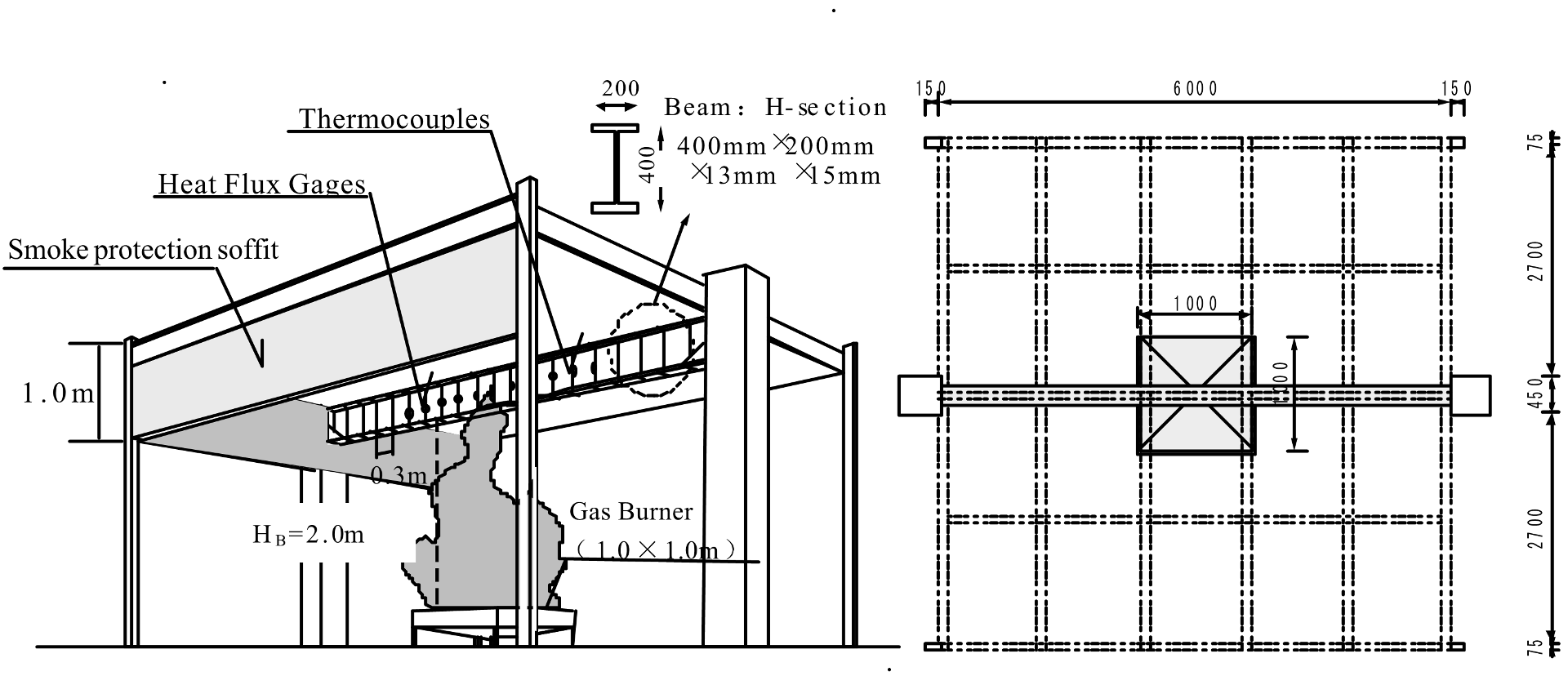

Figure HT2-2 shows a 6m steel beam subjected to a localised fire which is set just under the centre of the beam. This example is established according to the real-scale localised fire tests reported by Wakamatsu and Hasemi.

Please refer to this paper: Thermal analysis infrastructure in OpenSees for fire and its smart application interface towards natural fire modelling, Fire Technology,2020

| OpenSees Model | Type used for this example |

|---|---|

| HT Entity | Isection3D, I-section (400mm*200mm*13mm*15mm) |

| Material | CarbonSteelEC3 |

| Fire Type | Localised fire (1127kW) |

Download: This Example Package

Model Geometry

The construction size of the real-scale localised fire tests is 6.0m × 6.0m × 3.4m (Ceiling Height). The observed steel beam under the centre of the ceiling is a 150mm(H) × 75mm(W) × 5(Web) × 6mm(Flange) H-shape section. A rectangular gas burner 1.0m × 1.0m was setting in the centre of the floor with 1.0m vertical height. This burner used propane as the fuel. The heat release rates are in equivalent to different fire sizes controlled by the volume of flowing gas and assumed complete combustion. *The real-scale localised fire tests without protection soffit.

Tcl scripts for model definition

set BF 0.20;

set HB 0.40; set Len 6.0;

##Width of flange, Height of beam,#Length of beam (m)

set Tw 0.013; #Thickness of web (m)

set Tf 0.015; #Thickness of flange (m)

set Centrex 0.0

set Centrey [expr $HB/2.0] #Centrey=HB/2.0

set Centrez [expr $Len/2.0] #Centrez=Len/2.0

#Mesh sizes;

set elex [expr ($BF-$Tw)/8.0];

set eleweby [expr ($HB-$Tf*2.0)/10.0];

set eley [expr $Tf/2.0]

set elewebx [expr $Tw/2.0]

set elez [expr $Len/120.0]

#activates the HTModule.

HeatTransfer 3D;

#Defining HeatTransfer Material with Material tag 1

HTMaterial CarbonSteelEC3 1;

#define Heat Transfer Entity;

HTEntity Isection3D 1 $Centrex $Centrey $Centrez $BF $HB $Tw $Tf $Len;

#HTMesh $MeshTag $EntityTag $MaterialTag -SecondMat 2

HTMesh 1 1 1 -phaseChange 0 -MeshCtrls $elex $eley $elez $elewebx $eleweby

HTMeshAll;

puts "mesh done";

#Defining Initial Temperature (K);

SetInitialT 293.15;

#Defining HeatTransfer constants $consTag $hc(W/m^2∙K) $Ta $ε $a

HTConstants 1 35.0 293.15 0.85 0.85;

#Defining HeatTransfer Boundary Pattern

HTPattern AmbientBC 1 {

HeatFluxBC -HTEntity 1 -face 1 4 5 6 7 8 9 -type -ConvecAndRad -HTConstants 1;

}

FireModel Localised 1 -origin 0.0 -2.0 $Centrez -firePars 1.0 1127.0E3 2.4 2 ;

HTPattern fire 2 model 1 {

HeatFluxBC -HTEntity 1 -face 1 -type -Prescribed -HTConstants 1 -par 4; #Fire action using input heat flux

HeatFluxBC -HTEntity 1 -face 4 5 -type -Prescribed -HTConstants 1 -par 3;

HeatFluxBC -HTEntity 1 -face 6 7 -type -Prescribed -HTConstants 1 -par 2;

HeatFluxBC -HTEntity 1 -face 8 9 -type -Prescribed -HTConstants 1 -par 1;

#'HTEntitiy' $entTag, 'face' $fTag, 'type' $HFType, 'HTConstants' consTag

#-par is to set extra tags for SFPE beam-ceiling localised fire model. User can leave as it is

}

#HeatTransfer Recorder

set flloc [expr ($BF-$Tw)/4.0+$Tw/2]

HTNodeSet 10 -Locx $flloc -Locy 0.0075;

HTRecorder -file tempBLF.out -NodeSet 10; #Nodes of beam lower flange

HTAnalysis HeatTransfer

HTAnalyze 108 10;

wipe;

Output Results

The temperature distributions of the steel beam are shown in the following figure.

Jiang, L., Jiang, Y.,Zhang, Z., Usmani, A. Thermal analysis infrastructure in OpenSees for fire and its smart application interface towards natural fire modelling, Fire Technology,2020

This page is created by Liming Jiang & Zhuojun Nan, 2020