A simply supported composite beam subjected to test temperatures.

Developed by Dr. Mustesin Ali Khan

Introduction

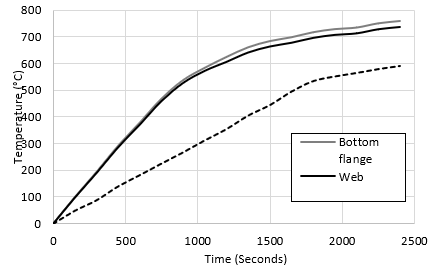

Figure-1 shows a 4.53 m simply supported composite beam. Static loads of P = 32.47 kN are applied as shown in Figure 1. The bottom flange, web, top flange and slab of the beam are subjected to a temperature as recorded during experiments. 152 beam elements are used for modelling the steel beam as well as concrete slab and rigid link connection is assumed between concrete slab and steel beam. Material class Steel01Thermal and ConcreteECThermal are used for steel beam and concrete slab, respectively. A comparison, of midspan deflection is presented with test results.

| OpenSees Model | Type used for this example |

|---|---|

| Element | DispBeamColumnThermal |

| Section | FiberSectionThermal |

| Material | ConcreteECThermal, Steel01Thermal |

| Thermal Loading | Beam2DThermalAction ---Test temperatures |

Download: This Example Package

Model Geometry

Tcl scripts for model definition

Simply Supported Beam model

####################################################################################

# composite beam with Simply supported bounary conditions exposed to fire

# total 151 elements for 4530 mm beam ;

# Four point load P=32.47 kN; thermal history in accordence with tests (Wianman and Kirby);

# 8 fibers for both the slab and steel beam section;

# Material class Steel01Thermal is used for steel and Concrete02Thermal for concrete;

# unit i.e. mm, N, MPa

# Written: Mustesin Ali Khan

# July 2020, The Hong Kong Polytechnic University

wipe;

model BasicBuilder -ndm 2 -ndf 3;

source DisplayPlane.tcl

source DisplayModel2D.tcl

# define NODAL COORDINATES FOR BEAM

for {set level 1} {$level <=152} {incr level 1} {

set X [expr ($level-1)*30];

set nodeID $level

node $nodeID $X 0; # actually define node

}

# define NODAL COORDINATES FOR SLAB

for {set level 1001} {$level <=1152} {incr level 1} {

set X [expr ($level-1001)*30];

set nodeID $level

set loc 193.0

node $nodeID $X $loc; # actually define node

}

#define boundary condition;

fix 1 1 1 0;

fix 1001 1 1 0;

fix 152 0 1 0;

fix 1152 0 1 0;

#define RIGID LINKS

set type beam

for {set level 2} {$level <=151} {incr level 1} {

set masterNodeTag $level;

set slaveNodeTag [expr $level+1000]

rigidLink $type $masterNodeTag $slaveNodeTag; # actually define rigid link

}

#define material

uniaxialMaterial Steel01Thermal 1 255 2e5 0.01; # for steel beam

uniaxialMaterial Steel01Thermal 3 600 2.1e5 0.01; # for reinforcement in slab

set fpc -30

set epsc0 -0.003

set fpcu [expr $fpc*0.05];

set epsU -0.02

set lambda 0.1

set ft 0.0

set Ets [expr $ft/0.002];

uniaxialMaterial ConcreteECThermal 2 $fpc $epsc0 $fpcu $epsU $lambda $ft $Ets

# beam sections:

# d 398.0; # depth

# bf 141.8; # flange width

# tf 8.6; # flange thickness

# tw 6.4; # web thickness

#define fibred section for steel beam;

section fiberSecThermal 1 {

fiber -125.35 0 918.8 1;

fiber -110.05 0 918.8 1;

fiber -101.43 0 220.2 1;

fiber -72.46 0 220.2 1;

fiber -43.49 0 220.2 1;

fiber -14.52 0 220.2 1;

fiber 14.52 0 220.2 1;

fiber 43.49 0 220.2 1;

fiber 72.46 0 220.2 1;

fiber 101.43 0 220.2 1;

fiber 110.05 0 918.8 1;

fiber 125.35 0 918.8 1;

}

#define fibred section for concrete slab;

section fiberSecThermal 2 {

fiber -56.87 0 10432.5 2;

fiber -40.62 0 10432.5 2;

fiber -24.37 0 10432.5 2;

fiber -8.12 0 10432.5 2;

fiber 8.12 0 10432.5 2;

fiber 24.37 0 10432.5 2;

fiber 40.62 0 10432.5 2;

fiber 56.87 0 10432.5 2;

#fiber -25 0 367.575 3;

layer straight 3 4 50.24 -50 -250 -50 250

}

geomTransf Corotational 1;

#ELES FOR BEAMS

for {set level 1} {$level <=151} {incr level 1} {

set node1 $level

set node2 [expr $node1+1]

set eleID $level

element dispBeamColumnThermal $eleID $node1 $node2 5 1 1; # actually define element

}

#ELES FOR SLAB

for {set level 1001} {$level <=1151} {incr level 1} {

set node1 $level

set node2 [expr $node1+1]

set eleID $level

element dispBeamColumnThermal $eleID $node1 $node2 5 2 1; # actually define element

}

recorder Node -file node6_RigidLink.out -time -node 75 -dof 2 disp;

# Define DISPLAY -------------------------------------------------------------

set xPixels 1000; # height of graphical window in pixels

set yPixels 490; # height of graphical window in pixels

set xLoc1 10; # horizontal location of graphical window (0=upper left-most corner)

set yLoc1 10; # vertical location of graphical window (0=upper left-most corner)

set ViewScale 2; # scaling factor for viewing deformed shape, it depends on the dimensions of the model

DisplayModel2D DeformedShape $ViewScale $xLoc1 $yLoc1 $xPixels $yPixels 0

# apply UDL Load

pattern Plain 1 Linear {

#CREATE UNIFORM LOADS FOR BEAMS

set P -32470;

load 19 0 $P 0;

load 56 0 $P 0;

load 94 0 $P 0;

load 132 0 $P 0;

}

constraints Transformation;

numberer Plain;

system BandGeneral;

test NormUnbalance 1.0e-2 100;

algorithm Newton;

integrator LoadControl 0.1;

analysis Static;

analyze 10;

loadConst -time 0.0

# PATTERN AND TIME SERIES FOR STEEL

pattern Plain 2 Linear {

for {set level 1} {$level <=151} {incr level 1} {

set eleID $level

eleLoad -ele $eleID -type -beamThermal -source "Steeltemp.dat" -128.5 128.5 ;

}

}

# PATTERN AND TIME SERIES FOR CONCRETE

pattern Plain 3 Linear {

for {set level 1001} {$level <=1151} {incr level 1} {

set eleID $level

#eleLoad -ele $eleID -type -beamThermal $TbotSlab -$Hslab $TtopSlab $Hslab ;

eleLoad -ele $eleID -type -beamThermal -source "Slabtemp.dat" -65 65;

}

}

# Start of analysis generation

# ------------------------------

# create the system of equations

system UmfPack

# create the DOF numberer

numberer Plain

# create the constraint handler

constraints Transformation

# create the convergence test

test NormDispIncr 1e-1 100;

#test NormUnbalance 1.0e-12 25

#test EnergyIncr 1.0e-12 25

# create the integration scheme

integrator LoadControl 150

# create the solution algorithm

algorithm KrylovNewton

# create the analysis object

analysis Static

# ------------------------------

# Finally perform the analysis

# ------------------------------

analyze 16

# --------------------------------

# End of analysis

Output Results

Midspan vertical displacement

Wainman D.E. and Kirby B.R. Compendium of UK standard fire test data unprotected structural steel-1. British Steel Corporation, Ref. No. RS/RSC/S10328/1/98/B. Swinden Laboratories, Rotherdam, 1988.

This page is created by D.V.V. Ramakanth, 2020