Comparision of material models: Steel01Thermal, Steel02Thermal and SteelECThermal using a restrained beam example

Developed by Domada Veera Venkata Ramakanth

Introduction

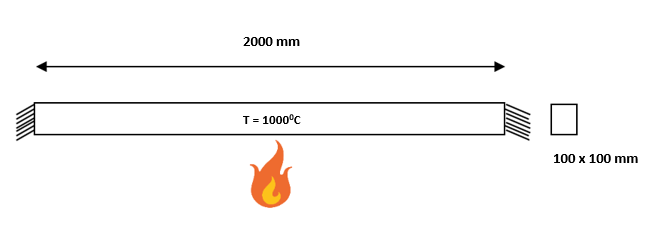

Figure-1 shows a restrained beam subjected to a temperature rise. The beam has been modelled using three existing steel models catering for thermal material degradation. The temperature load has been appl;ied on the left half portion of the beam. Displacement of the middle node and reaction at the right support have been compared in all three cases.

| OpenSees Model | Type used for this example |

|---|---|

| Element | DispBeamColumnThermal |

| Section | FiberSectionThermal |

| Material | Steel01Thermal, Steel02Thermal, SteelECThermal |

| Thermal Loading | Linear temperature rise over the left half of the member |

Download: This Example Package

Model Geometry

Tcl scripts for model definition

Restrained Beam model

wipe;

set s1 1;

set s2 2;

set s3 3;

model BasicBuilder -ndm 2 -ndf 3

# node $NodeTag $XCoord $Ycoord

node 1 2000 0

node 2 1000 0

node 3 0 0

# fix $NodeTag x-transl y-transl z-rot

fix 1 1 1 1

fix 3 1 1 1

# Geometric Transformation

geomTransf Linear 1

geomTransf PDelta 2

geomTransf Corotational 3

#uniaxialMaterial Steel01Thermal $matTag $Fy $E0 $b <$a1 $a2 $a3 $a4>

uniaxialMaterial Steel01Thermal 1 500 2e+05 0.15

#uniaxialMaterial Steel02Thermal $matTag $Fy $E0 $b $R0 $cR1 $cR2 <$a1 $a1 $a1 $a1>

uniaxialMaterial Steel02Thermal 2 500 2e+05 0.15 20 0.925 0.15 0 1 0 1 0

#uniaxialMaterial SteelECThermal $matTag <$steelType> $Fy $E0

uniaxialMaterial SteelECThermal 3 500 2e+05

section fiberSecThermal 155 -GJ 10000 {

#patch quad $matTag $numSubdivIJ $numSubdivJK $yI $zI $yJ $zJ $yK $zK $yL $zL

patch quad $s1 10 10 -50.0 -50.0 50.0 -50.0 50.0 50.0 -50.0 50.0

}

# element dispBeamColumn $eleTag $iNode $jNode $numIntgrPts $secTag $transfTag

element dispBeamColumnThermal 1 3 2 3 155 1 -mass 0

element dispBeamColumnThermal 2 2 1 3 155 1 -mass 0

recorder Node -file Node_displacements-s1.out -node 2 -dof 1 disp

# recorder Node -file Node_rotations.out -time -nodeRange 1 3 -dof 3 disp

recorder Node -file Node_forceReactions-s1.out -node 3 -dof 1 reaction

# recorder Node -file Node_momentReactions.out -time -nodeRange 1 3 -dof 3 reaction

# recorder Element -file DispBeamColumn_localForce.out -time -ele 1 2 localForce

# recorder Element -file DispBeamColumn_basicDeformation.out -time -ele 1 2 basicDeformation

# recorder Element -file DispBeamColumn_plasticDeformation.out -time -ele 1 2 plasticDeformation

puts "Running interval 1\n"

# Loads - Plain Pattern

pattern Plain 100 Linear {

eleLoad -ele 1 -type -beamThermal 1000 -50 1000 50.0

}

# recording the initial status

record

# Analysis options

system BandGeneral

numberer Plain

constraints Transformation

integrator LoadControl 0.01

test NormDispIncr 0.001 50 2

algorithm Newton

analysis Static

analyze 100

Output Results

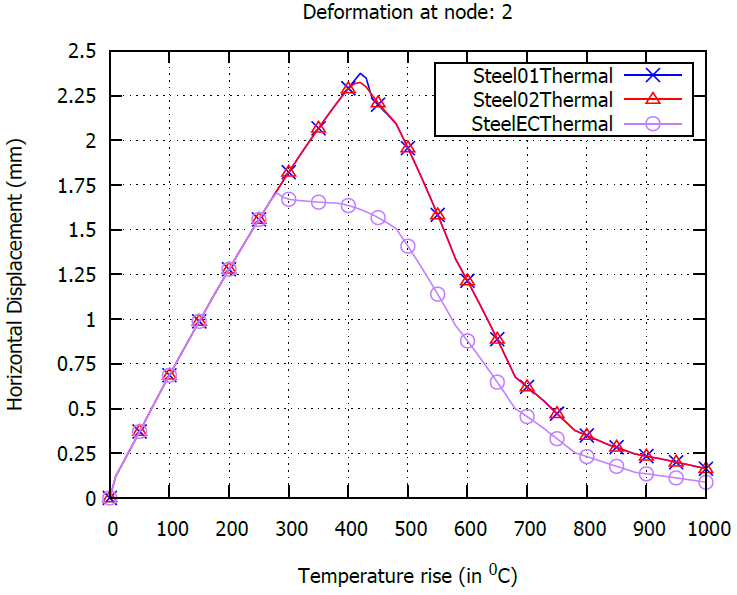

Comparision of horizontal displacement of the middle node

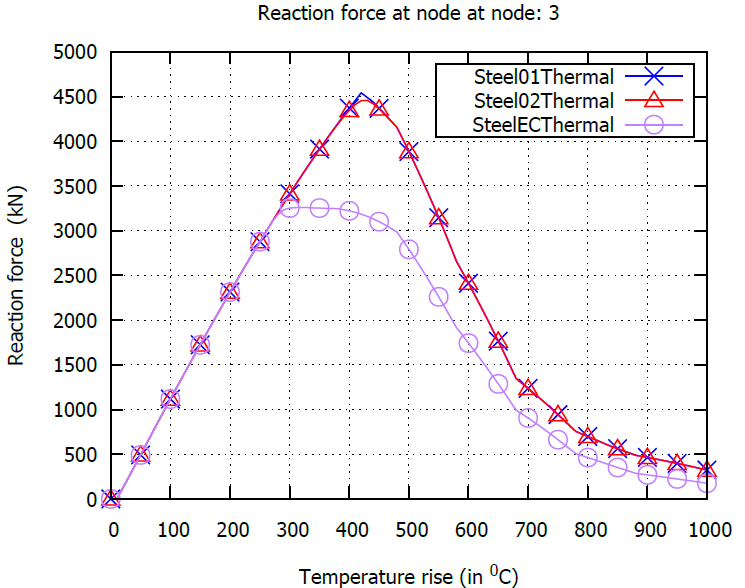

Comparision of reaction force at the right side support

Closed form solution

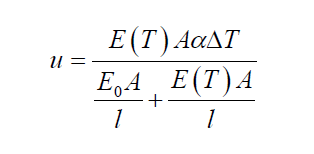

The solution can be verified using a closed form expression as shown given below.

Here u is the horizontal displacement of middle node, Eo and E(T) are the elastic modulous at ambient and elevated temperature respectively

This page is created by D.V.V. Ramakanth, 2020